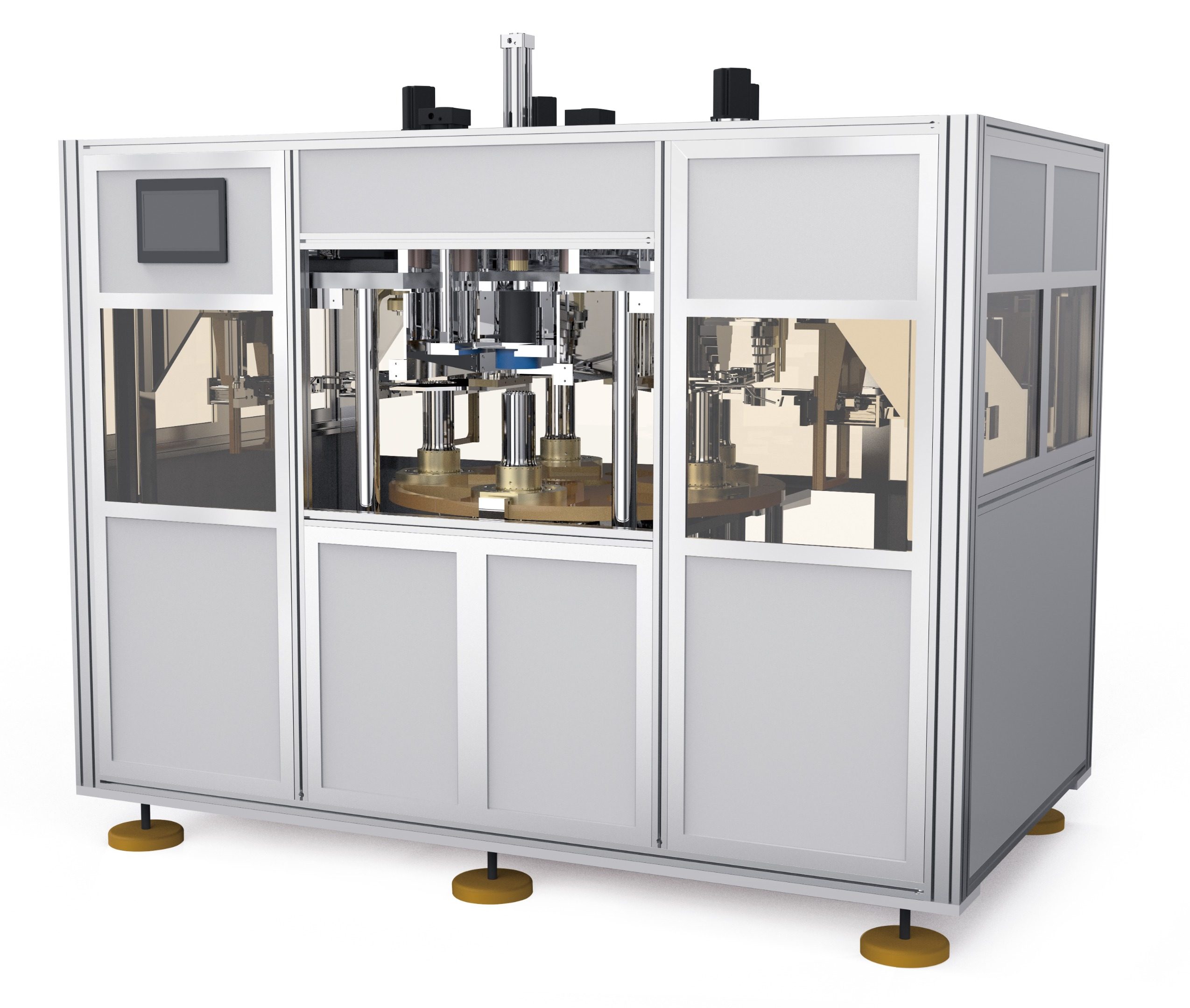

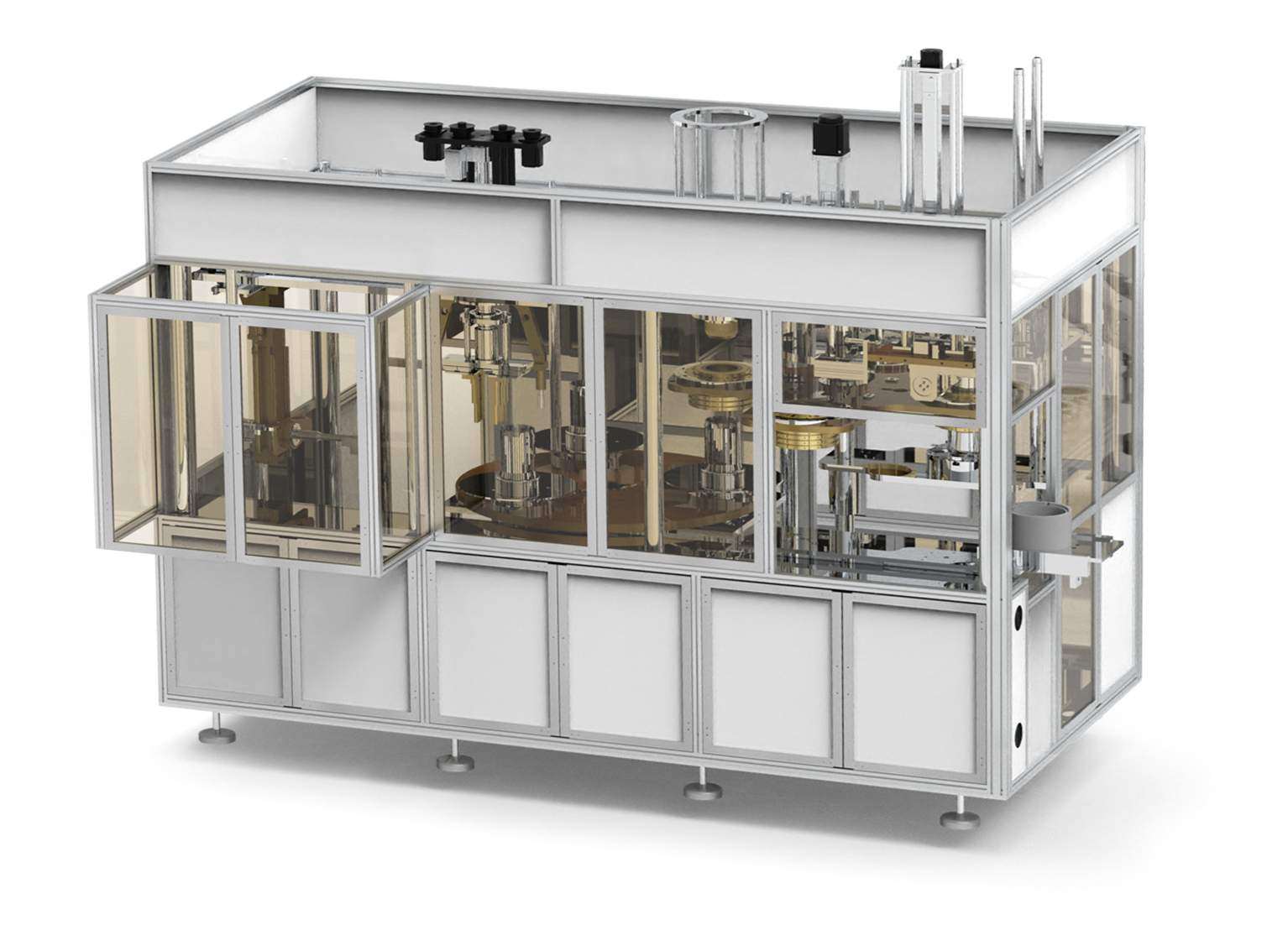

绕嵌一体机

设备拥有钢结构焊接框架,结构可靠性能稳定。

设备采用高效4轴勾线结构,能更好的对过桥线进行处理。

设备可根据绕组形式,定制绕线头的数量,达到不同节拍。

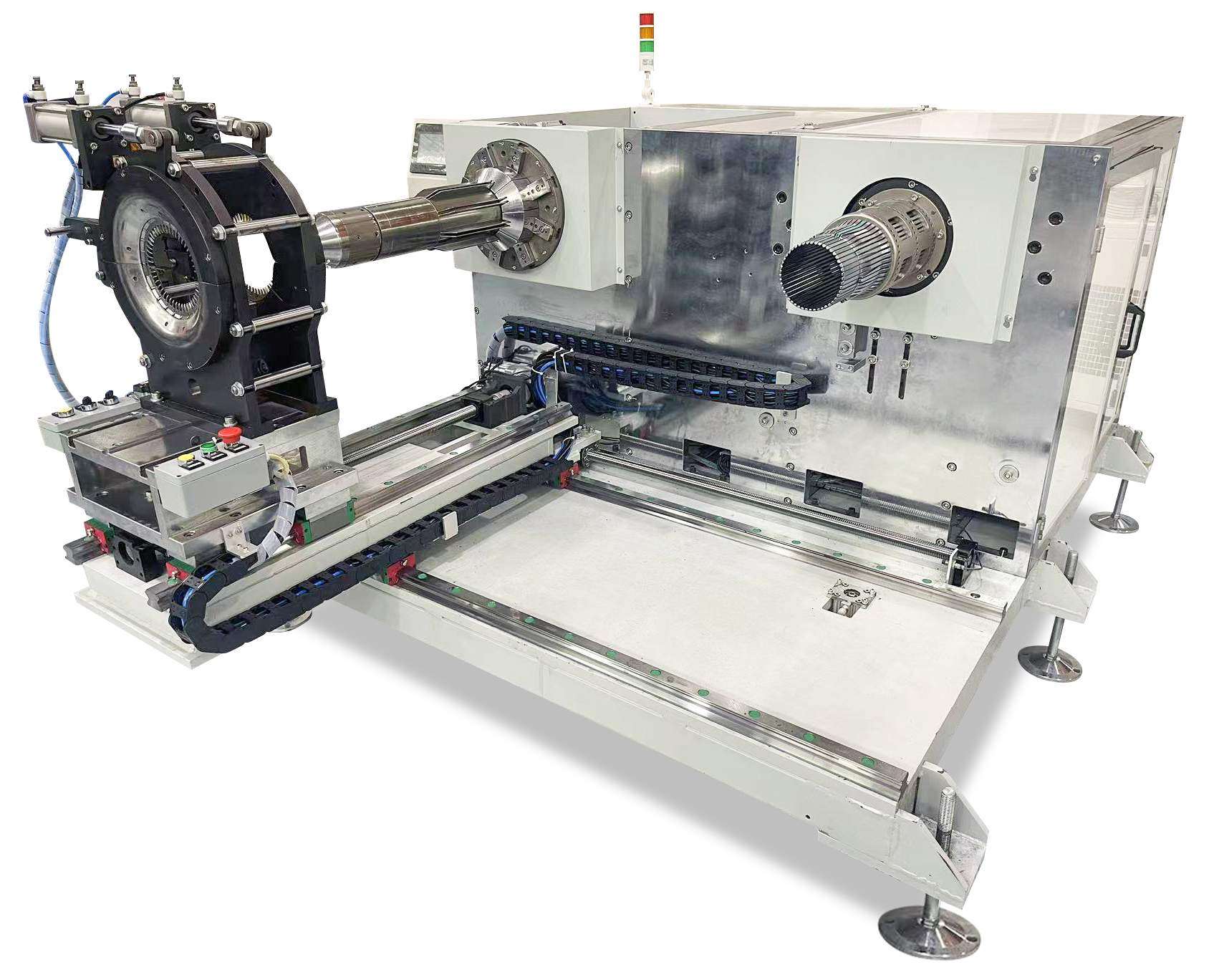

设备拥有行星齿轮绕线结构,可实现多根漆包线并绕。

设备绕线模可向前缩进,方便落线。

设备集成槽口单元,在绕线的同时完成槽口纸成形备料,并在嵌线时自动推入定子。

嵌线单元拥有3轴推进系统,可自由控制嵌线动作。

设备可根据客户要求增加线头拧紧功能,防止线头乱摆,并方便后道工序作业。

设备可以根据客户要求集成自动上下料机械手,提高自动化程度。

设备拥有更优的节拍和低噪音水平。

The equipment has a reliable and stable steel frame structure.

The equipment is equiped with a 4-axis wire manupilator, which gives more flexibility for handling the liason wire.

The equipment can customize the number of winding heads inorder to reach different cycle time.

The machine uses a planet gear flyer system that can perform mutiple parallel wire winding.

The machine is equipped with a movable winding form which makes it easy for dropping the wire into the tooling.

The machine has a wedge unit, that can prepare the wedges during the winding, the wedge will be inserted into the stator during the insertion.

The insertion unit has a three-axis pushing system, can define the insertion movements freely.

A terminal twisting system can be added to the winding unit, which can avoid the swing of the terminals during the process and make it much easier for the following process.

The equipment can intergrate a gripper in order to perform the stator loading/unloading automatically.

The machine offers optimized cycle time and lower noise level.