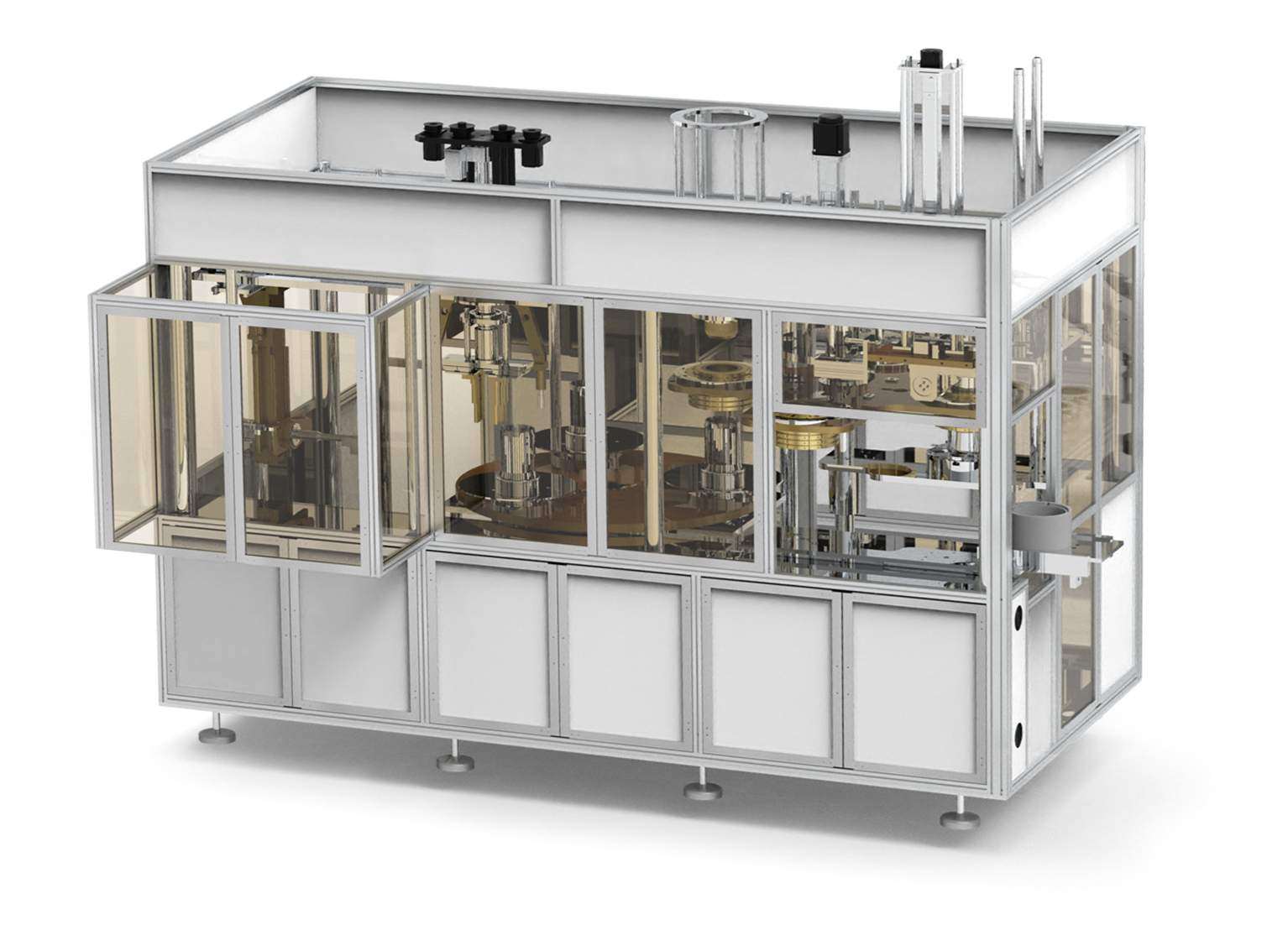

Winding&Inserting Machine

The equipment has a reliable and stable steel frame structure.

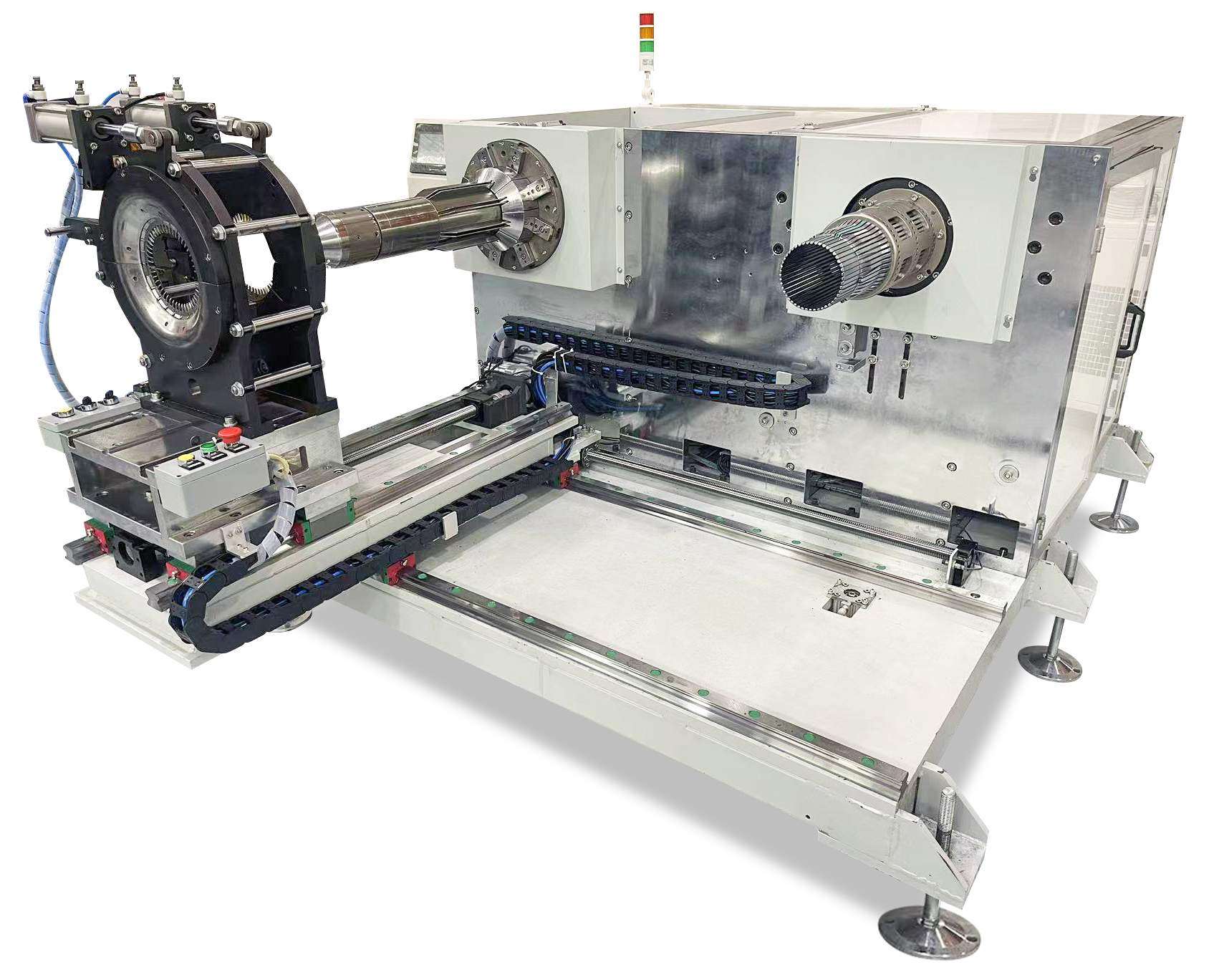

The equipment is equiped with a 4-axis wire manupilator, which gives more flexibility for handling the liason wire.

The equipment can customize the number of winding heads inorder to reach different cycle time.

The machine uses a planet gear flyer system that can perform mutiple parallel wire winding.

The machine is equipped with a movable winding form which makes it easy for dropping the wire into the tooling.

The machine has a wedge unit, that can prepare the wedges during the winding, the wedge will be inserted into the stator during the insertion.

The insertion unit has a three-axis pushing system, can define the insertion movements freely.

A terminal twisting system can be added to the winding unit, which can avoid the swing of the terminals during the process and make it much easier for the following process.

The equipment can intergrate a gripper in order to perform the stator loading/unloading automatically.

The machine offers optimized cycle time and lower noise level.