Winding&Inserting Machine

The equipment has a reliable and stable steel frame structure. The equipment is equiped with a 4-axis wire manupilator, which gives more flexibility for handling the liason wire. The equipment can customize the number of winding heads inorder to reach different cycle time. The machine uses a planet gear flyer system that can perform mutiple parallel wire winding. The machine is equipped with a movable winding form which makes it easy for dropping the wire into the tooling. The machine has a wedge unit, that can prepare the wedges during the winding, the wedge will be inserted into the stator during the insertion. The insertion unit has a three-axis pushing system, can define the insertion movements freely. A terminal twisting system can be added to the winding unit, which can avoid the swing of the terminals during the process and make it much easier for the following process. The equipment can intergrate a gripper in order to perform the stator loading/unloading automatically. The machine offers optimized cycle time and lower noise level.

Stator Cleating/Welding Machine

The equipment utilizes a mandrel expansion structure, ensuring precise stacking accuracy. Stator laminations can be finely calibrated, and the permissible lamination height tolerance range can be configured within the human-machine interface. You have the flexibility to freely adjust the lamination pressing force. The machine offers adjustable welding speed. The machine can perform welding on skewed welding slots. The modular design of our tooling fixtures facilitates swift mold changes. The equipment can be powered by a hydraulic or servo system. It features an automatic reset function, enabling seamless operation in automatic cycles. To prevent any mishandling, the equipment incorporates an interlocking function, safeguarding the fixtures from damage. You can opt for manual loading and unloading or seamlessly integrate the equipment into automated production lines, thereby enhancing overall efficiency.

Flat wire bending machine

Flat wire bending machine

Wave Winding Technology

Wave Winding Technology

Hairpin Technology

Dexun Technology has dedicated significant resources to studying hairpin technology. We've developed a comprehensive solution covering all key processes of hairpin stator production. Additionally, we've conducted research on continuous wave winding technology and now offer prototype services to facilitate small batch production for this innovative technology.

Vertical Inserting Machine

The equipment has a reliable and stable steel frame structure. The equipment uses a horizontal inserting structure. The machine has a wedge unit, that can prepare the wedges during the winding, the wedge will be inserted into the stator during the insertion. The insertion unit has a two-axis pushing system, can define the insertion movements freely. The machine offers optimized cycle time and lower noise level.

Slot Insulating machine

The equipment has a reliable and stable steel frame structure, and offers vertical and horizantal option for the customers. The equipment is equiped with material lacking alarm system, and can freely set the folding size on each side, as well as the height of the insulating paper. The cutting, fedding and the rotation of the stator are controlled by servo motor, and can be set freely. According to customer’s requirement, the equipment can also add the fuction of stator inspection including slot size, I.D, stack height and weight inspection. The equipment has one paper forming unit, which is suitalbe for single slot shape stator, and offers optimized cycle time and lower noise level.

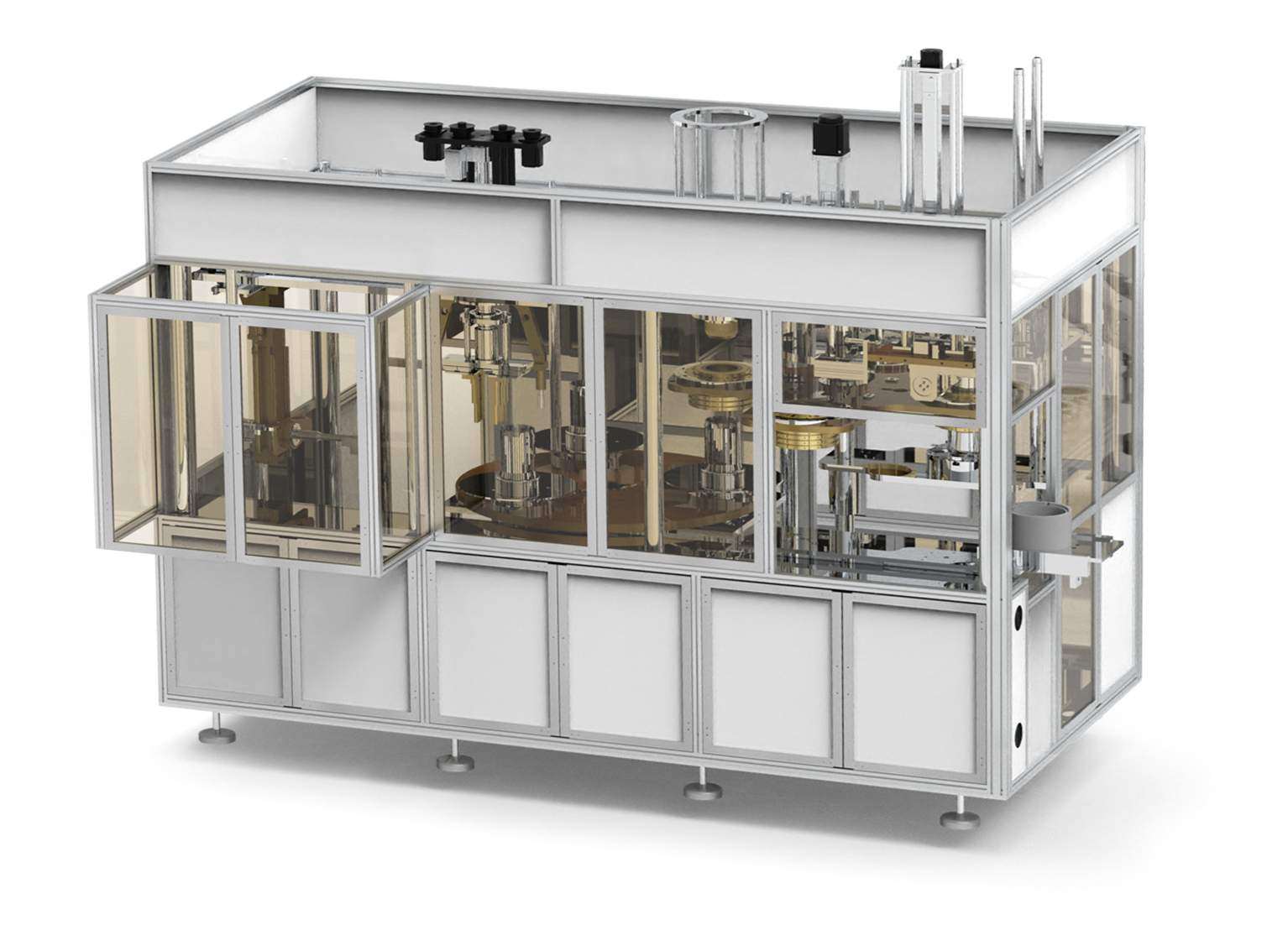

Coil Winding & Inserting & Expanding Center

The equipment has a reliable and stable steel frame structure. The equipment intergrates a coil expanding unit which will expand the coil between the phases. And the stator will not leave the machine before the all three phases are inserted. The coil expanding unit is driven by the servo motor system, allow you to define the precise movement. The coil expanding unit is also equipment will blades that will press the wedge during the process. The equipment is equiped with a 4-axis wire manupilator, which gives more flexibility for handling the liason wire. The equipment can customize the number of winding heads inorder to reach different cycle time. The machine uses a planet gear flyer system that can perform mutiple parallel wire winding. The machine is equipped with a movable winding form which makes it easy for dropping the wire into the tooling. The machine has a wedge unit, that can prepare the wedges during the winding, the wedge will be inserted into the stator during the insertion. The insertion unit has a three-axis pushing system, can define the insertion movements freely. A terminal twisting system can be added to the winding unit, which can avoid the swing of the terminals during the process and make it much easier for the following process. The equipment can intergrate a gripper in order to perform the stator loading/unloading automatically. The machine offers optimized cycle time and lower noise level.

Vertical Winding Machine

The equipment has a reliable and stable steel frame structure. The equipment is equiped with a 4-axis wire manupilator, which gives more flexibility for handling the liason wire. The equipment can customize the number of winding heads inorder to reach different cycle time. The machine uses a planet gear flyer system that can perform mutiple parallel wire winding. The machine is equipped with a movable winding form which makes it easy for dropping the wire into the tooling. The machine offers optimized cycle time and lower noise level.

Horizontal inserting machine

The equipment has a reliable and stable steel frame structure. The equipment uses a horizontal inserting structure and intergrates a pre-forming unit which will expand the coil between the phases. And the stator will not leave the machine before the all three phases are inserted. The coil expanding unit is driven by the servo motor system, allow you to define the precise movement. The coil expanding unit is also equipment will blades that will press the wedge during the process. The machine has a wedge unit, that can prepare the wedges during the winding, the wedge will be inserted into the stator during the insertion. The insertion unit has a three-axis pushing system, can define the insertion movements freely. The machine offers optimized cycle time and lower noise level.

Brushless stator needle winding machine

The equipment has a reliable and stable steel frame structure. The equipment is suitable for stator with multiple parallel wire and big wire size, and offers short cycle time and high efficiency, as well as lower defect rate. The unit is driven by a six-axis motion control module, which allows you to switch quickly between different product types. The machine offers optimized cycle time and lower noise level.

Mutil-Station Brushless Stator Needle Winding Machine

The equipment has a reliable and stable steel frame structure. The equipment is suitable for stator with multiple parallel wire and big wire size, and offers short cycle time and high efficiency, as well as lower defect rate. The unit is driven by a six-axis motion control module, which allows you to switch quickly between different product types. The machine offers optimized cycle time and lower noise level.

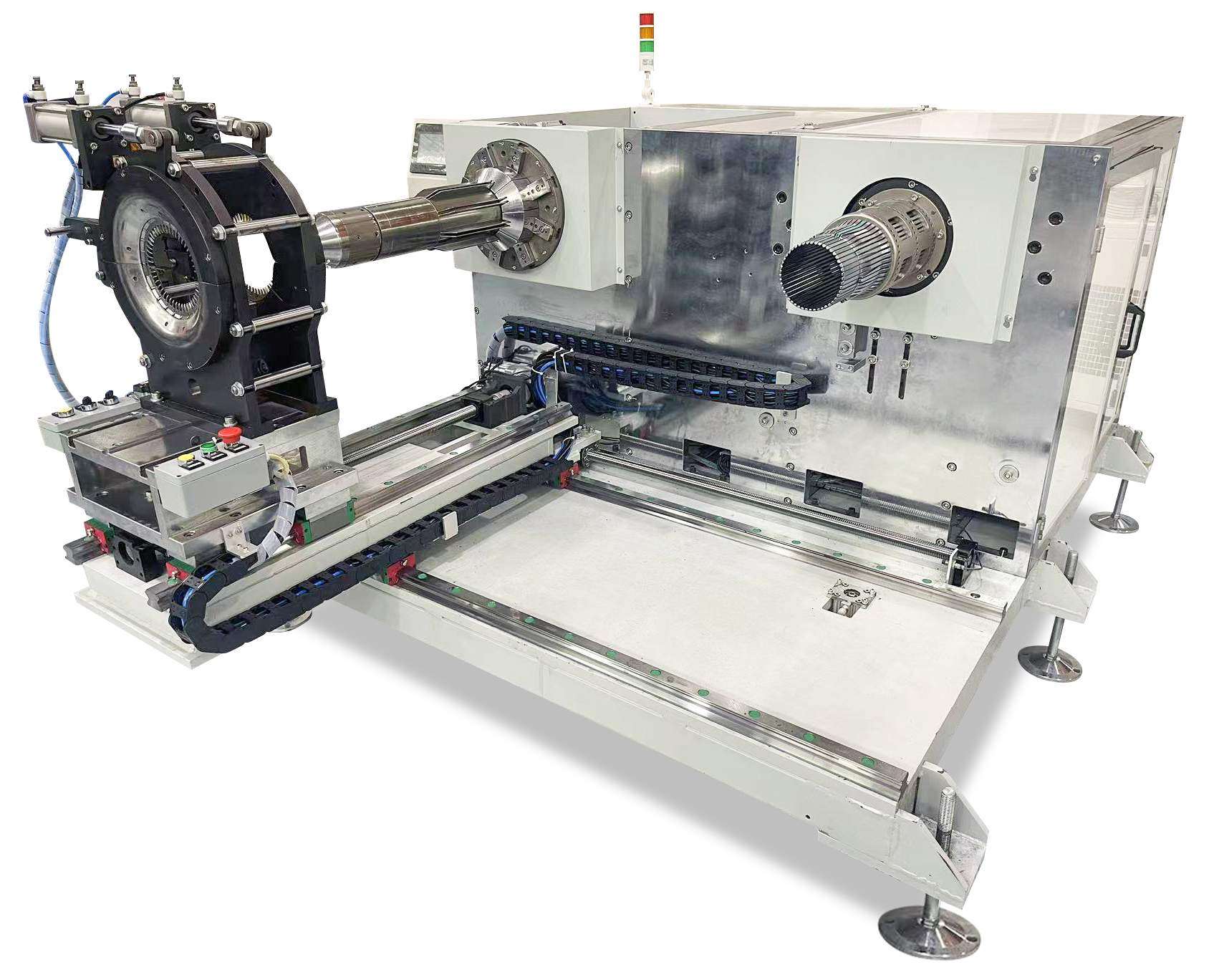

Needle winding machine for Rotor

The equipment has a reliable and stable steel frame structure. Winding and wire alignment are consistent, neat and in order, there is no slack coil in the winding, and no coil "collapse". During the winding process, he coil has no twisting defects, no crossing between wires, and no knotting, neither fly wire. No intermediate forming for copper and aluminum wires. The fine arrangement and winding can be completed at one time. Layered wiring can also be carried out. Each layer of equipment can accurately adjust the wiring distance and the number of winding turns. It only needs to replace the fixed mandrel and adjust the winding parameters to change between different stack height of the same lamination (about 10min). If switching between different laminations, it is necessary to replace the inner and outer protective molds and the fixed mandrel, and change the winding parameters (about 20min). The machine offers optimized cycle time and lower noise level.

Welding Machine

Equipped with Siemens 1200 series PLC, our system offers a comprehensive set of features

Stator Pre-forming Machine

The equipment has a reliable and stable steel frame structure. The unit is driven by all servo motor system, which allows you to make a precise forming to the O.D, I.D and height of the stator coil. All the tooling are polished carefully, in order to avoid scratching the wire during the forming. The machine offers optimized cycle time and lower noise level.

Coild Final forming machine

The equipment has a reliable and stable steel frame structure. The unit is driven by all servo motor system, which allows you to make a precise forming to the O.D, I.D and height of the stator coil. All the tooling are polished carefully, in order to avoid scratching the wire during the forming. The machine offers optimized cycle time and lower noise level.

Lacing Machine

The equipment has a reliable and stable steel frame structure. The lacing machine can make diamond stitch on the coils of each side of the stator at the same time. The rotation of the stator is driven by servo motor. The movements of the needle and shuttle are also driven by servo motor, allow you to make subtle adjustment. After the lacing, the iron will fuse the lacing cord automatically. The machine offers optimized cycle time and lower noise level.

Automatic Stator Production Line

The line intergrate the following production process. - Stator insulating - Stator winding, inserting and coil expanding - Stator pre-forming - Stator center star welding - Stator final forming - Stator lacing - Stator terminal welding - Stator slot expanding - Stator electrical test The stator insulating and winding and inserting are connected with a 6-axis robot, and the other stations are using chain conveyor and grippers to connect. The line is suitable for EV and Servo motor stator production.

Spare Parts

We provide a comprehensive range of spare parts essential for motor production, encompassing items such as guides, fixing guides, wire pushers, wedge pushers, wire transfer tools, insertion kits, lacing needles, and winding forms. All of our parts are crafted from high-quality raw materials, including steel, copper, iron, aluminum, and more. These premium materials guarantee excellent quality and durability, ensuring the longevity of your equipment. The parts boast a stable structure, exceptional dimensional accuracy, and minimal tolerance. The product is characterized by its high hardness, excellent wear resistance, remarkable tensile strength, consistent thermal performance, and an extended life. We offer the flexibility to manufacture products according to customer drawings or to redesign and customize them based on existing equipment and products, tailored to the unique requirements of our customers.

No data.No Data.